| Our services | Laboratory rotating equipment (manufacturing, designing, sales, repair, etc.) |

|---|---|

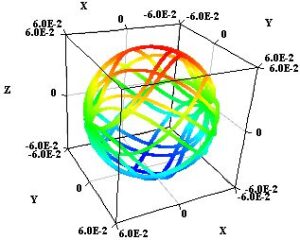

| merchandise list | ・3D SPIN REACTOR Our unique 3D spin reactor utilizes high-speed 3D rotation to solve mixing, dispersion, crushing, etc. that were previously impossible. The target is highly uniform mixture and dispersion of substances with specific gravity and viscosity difference. We are good at mixing and dispersing organic substances without the use of surfactants.  ・Homogenizer It can be used for mixing, dispersing and crushing using shear force. It is inexpensive, easy to operate and has excellent durability.  ・Kneading equipment A defoaming kneading equipment that utilizes the centrifugal force of the inner diameter. Ideal for kneading paints and adhesives that have removed air bubbles.  ★Differentiate with unique “manufacturing”. |

| 3D SPIN REACTOR Equipment usage example |

・Battery materials (positive electrode material, negative electrode material) are mixed and dispersed. ・Mixing and crushing of all solid state battery materials. ・Mixing and crushing of multilayer capacitors. ・CNT mixing, dispersion, and crushing. ・Mixing and dispersion of conductive paste & ink for electronics. (For example, mixing and dispersion of metals and resins with different specific gravities) ・Mixing and dispersion of special ink for printers. (For example, mixing, dispersion of metal, glass and organic solvent) ・Mixing and dispersion of fluorescent materials and magnetic materials. ・Mixing and dispersion of photoresist materials. ・Compound of ink and abrasive. ・ Thermoforming type in-mold electronics, mixing, dispersion. ・Electromagnetic shield, mixing, dispersion. ・Mixing and dispersion of 3D printer modeling materials. (Mixing and dispersion of ceramics and resin) ・Mixing and dispersion of organic EL materials. ・Multiple special solvents, emulsion (emulsification) of acrylics, mixing, dispersion. ・Mixing, dispersion and emulsification of pharmaceuticals and cosmetics that are sensitive to heat changes. ・Optical division of medicines. |

| 3D SPIN REACTOR Product introduction benefits |

・Reduces the use of surfactants ・Reduced manufacturing loss (irregularity) by improving uniformity. ・Creation of innovative materials by improving uniformity. ・Reduction of raw material costs through miniaturization and highly uniform mixing. ・Reduced manufacturing time and labor costs. ・Introduced a manufacturing method that could not be resolved with existing equipment. (Differentiation from other companies) |