【Background of increasing demand for mixing – Problem structure –】

Agglomeration, fever, and dispersion at the time of mixing and dispersion occur chronically, affecting profits.

Material development/manufacturing issues and 3D SPIN REACTOR solutions

【Task】

・Two-dimensional rotation causes high specific gravity particles to aggregate at the bottom.

・One point of strong impact may cause high temperature.

・Variation in particle size during mixing and crushing is an issue

・Shear heat is generated when the blade is used

【Solution for 3D SPIN REACTOR】

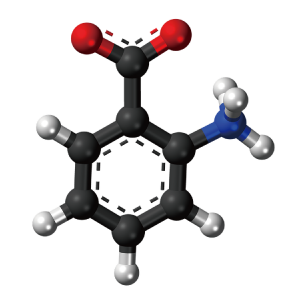

・3D SIPN REACTOR achieves non-aggregation when mixed and dispersed

・Can be mixed and dispersed without using a surfactant

・Achieves low heat generation by utilizing frictional motion

・Realization of single peak mixing and dispersion

・Realize uniform mixing and dispersion of non-uniform materials

Non-aggregated

Can be operated without the use of surfactants because it does not aggregate

No variation in particle size

Provides stable grain size

No impact heat

Not affected by impact heat

No shear heat

Not affected by shear heat

Low heat

Features low heat generation that utilizes frictional force like a mortar